TM 11-6130-392-34

3-5. Voltage, Resistance, and Waveform Measure-

3-4. Repainting and Refinishing

ments

Fault isolation procedures are specified in para-

Touchup of small damaged areas of the battery charger

graph 3-12. Procedures specify when voltage, resis-

case and equipment case is authorized at direct support

tance, or waveform measurements are to be made,

level. Refer to TM 11-6130-392-12, operator and

and which test points to be used. Illustrations are

organization; maintenance manual, for instructions.

provided for identity and test point locations.

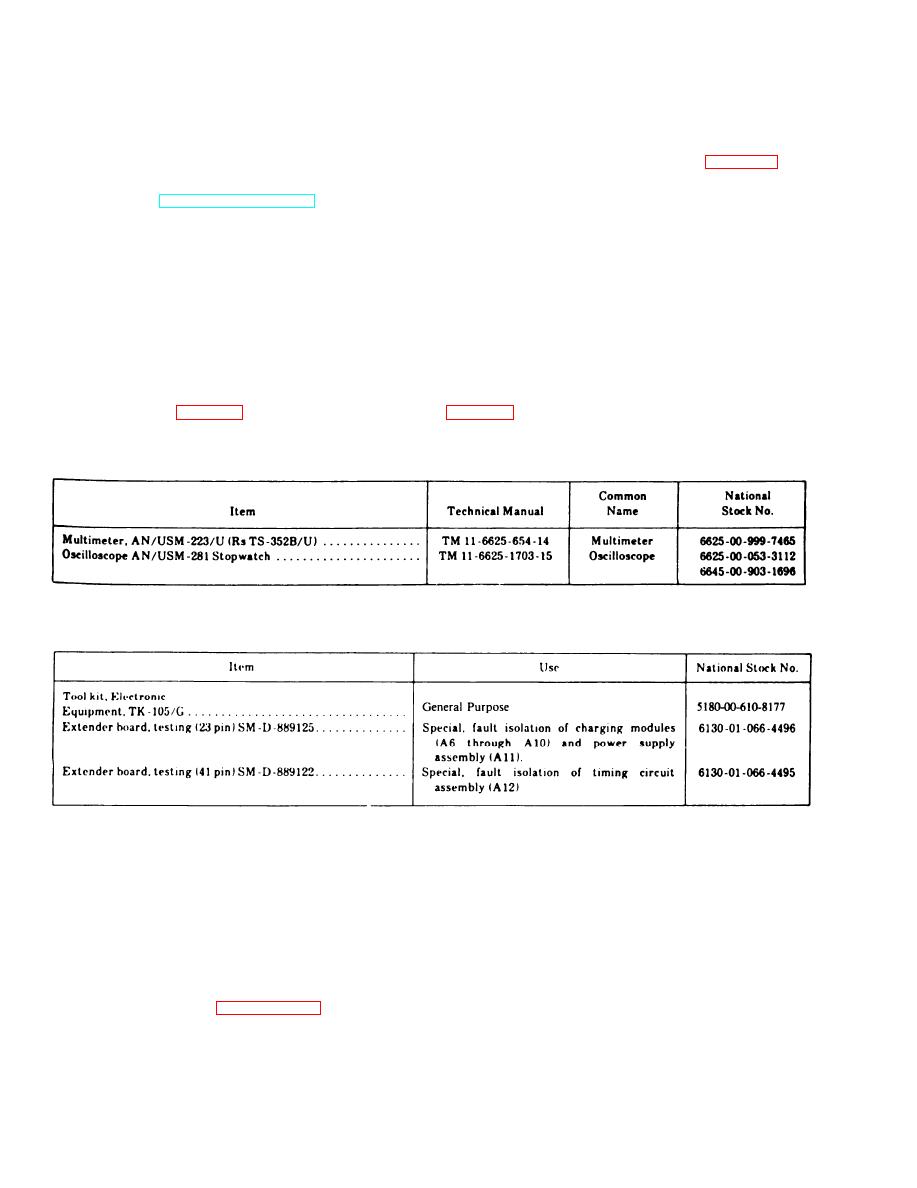

Section II. TOOLS AND EQUIPMENT

3-6. Test Equipment, Tools, and Materials

b. Tools and Materials. Tools and materials re-

a. Test equipment. Test equipment required for

q u i r e d for direct support maintenance, including

special tools required for fault isolation, are listed in

direct support maintenance of Battery Charger PP-

7286/U is listed in table 3-1.

Table 3-1. Test Equipment

Table 3-2. Tools and Materials

Section III. TROUBLESHOOTING

3-7.

Troubleshooting-General

3-8. Troubleshooting Test Sequence

This section contains instructions for troubleshooting

a. Visual inspection. Before performing tests,

Battery Charger PP-7286/U. Direct support personnel

visually inspect the battery charger to find faults.

will replace faulty components, which are limited to the

Prevent tests that are not necessary to locate an

specific list contained in paragraph 3-3. Replacement

easily-seen fault.

procedures are included in section IV. Test procedures

b. Test sequence. The test sequence for trouble-

for use after replacing a component are included in sec-

shooting the battery charger and isolating faulty

tion V.

components, is:

3-2 Change 1