TM 10-6140-200-14

Section II. REPAIRING BATTERIES

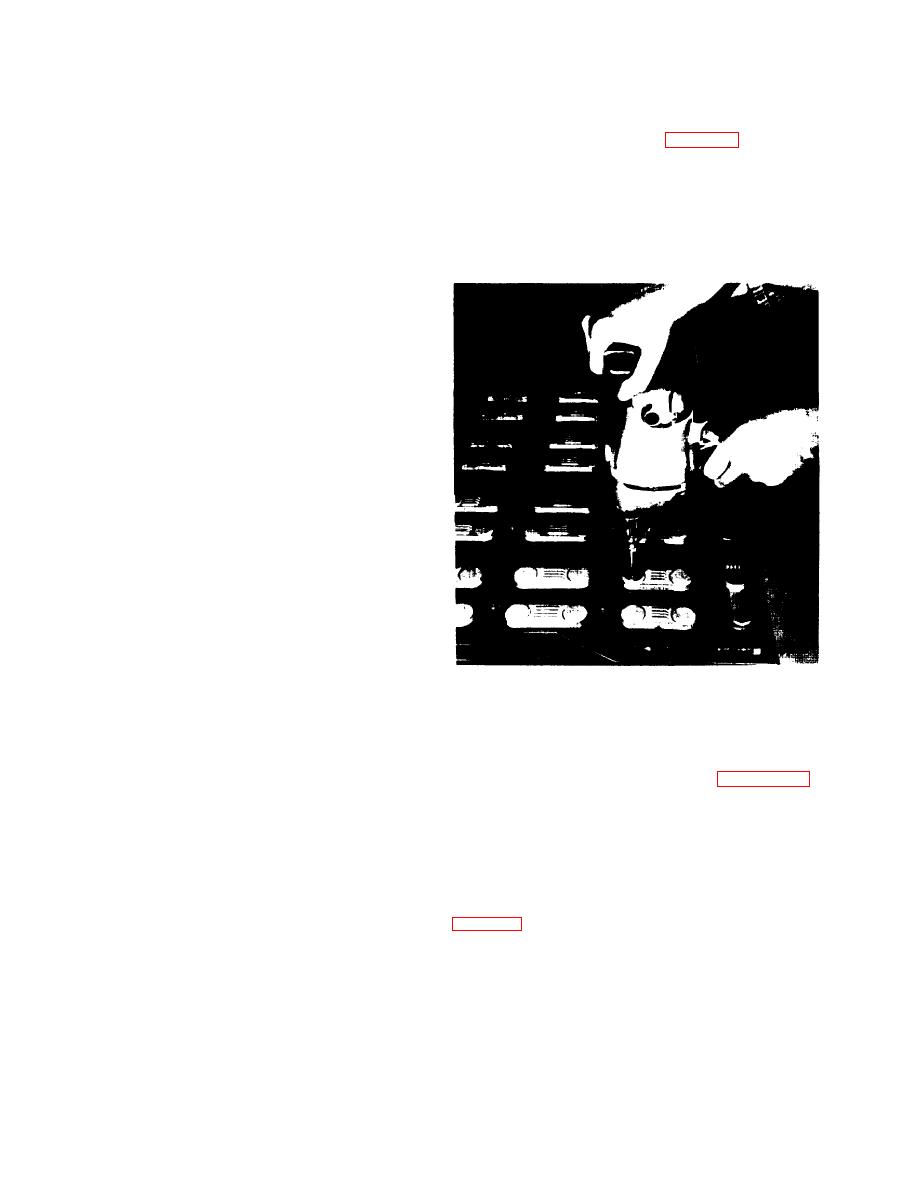

remain for rebuilding later. (See Figure 3-1). The drills

3-5. General

come in different sizes. When using them be careful to

cut only as deeply as necessary, usually 1/4" to 3/8".

a. Storage batteries which have been damaged or which

Make certain vent plugs are in place. During drilling try to

contain defective cells may, if the rebuilding cost and

center on the cover bushing and make sure any lead curl

time are justified, be restored to a serviceable condition.

produced does not short across other connectors. After

drilling, the intercell connectors can be lifted off with a

b. It is important to check a battery thoroughly if it has

pair of pliers.

been involved in an accident or if it is believed to be

defective. A neglected battery will continue to deteriorate

even when not in use. Usually rebuilding is justified if the

majority of cells are in good condition.

c. This section explains how to remove cells from a

battery and how to repair them if they are to be salvaged.

Some special tools and parts will be required depending

upon the work to be done. Reference will be made to the

use of such special devices but they will not be further

identified in this manual. Although there is much simi-

larity of tools and battery parts among the various

battery manufacturers, the differences that exist are

critical. For this reason you must, when replacing or

repairing cells, refer to the applicable battery manu-

facturers listing of special tools, accessories and replace-

ment parts. These will be referenced in the General

Services Administration, Federal Supply Catalog, FSC

Group 61, part 11, Class 6140-Batteries-Heavy Duty,

Electric Storage. Each manufacturer identifies all tools,

accessories and replacement parts by an appropriate part

number. Use this number when making reference to them.

d. The General Services Federal Supply Catalogs can be

requisitioned from: General Services Administration, Cen-

tralized Mailing Lists Services, Building 41, Denver Fed-

eral Center, Denver, CO 80225.

Figure 3-1. Drilling cell connector

3-6. Purging of Gas

Before starting any repairs, remove all vent caps from

3-8. Removing a Complete Cell

cells to be repaired as well as from all surrounding cells.

The space above the electrolyte must be cleared of

hydrogen gas before proceeding with repairs. This can be

isolate the cell from adjacent cells. This may require

accomplished by introducing a low volume air stream

cutting of compound or removal of spacers. Use a long

(volume and force equal to that produced by fanning

spatula or similar tool to free the cell from top to

each cell with a stiff piece of cardboard or other suitable

bottom When the jar walls are free the cell can be lifted

from the battery tray. All cells are heavy so a suitable

nonconducting material) into each cell for at least 30

seconds. Be very careful when using air so that the

lifting device, such as an electric hoist, is recommended.

electrolyte is not splashed out of the cell. Do not blow

Threaded post clamps or cell pullers are available which

breath into cells. Wear protective face shield or goggles,

can be burned or clamped to the posts, as shown in

rubber gloves and apron. After cells have been purged,

cover all vent openings with several layers of water

ing bar between the loops of the post clamps and hook

dampened cloth before starting repairs.

the hoist to this bar.

b. After removing the cell, neutralize any acid in the tray

3-7. Removing Intercell Connectors

with a soda solution and clean up the residue.

Each battery manufacturer offers special intercell con-

nector drills designed to cut the bond between the cell

c. When a cell or element is being pulled, it is advisable

post and the connector while permitting the post to

to have on hand both a replacement jar and a cover in

3-4