TM 11-6140-203-14-3

g.

Performance Test. Performance testing for a new battery, before placing it into service, consists of

discharge capacity and electrical leakage tests. A battery which passes both of these tests is considered to be

serviceable.

(1) Discharge Capacity Test.

(a) After charging (f above), allow the battery to rest (para 5-4) and check the electrolyte level (para 5-5).

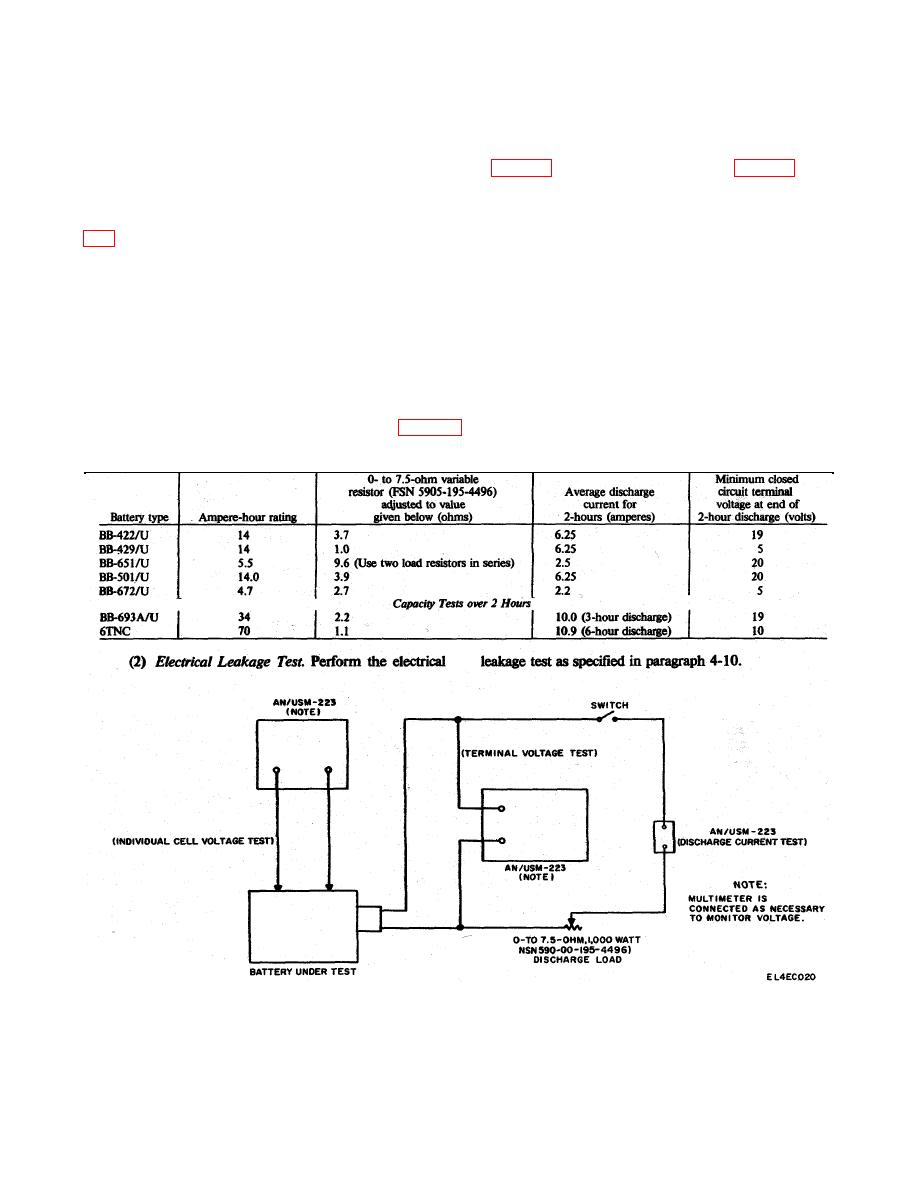

(b) Refer to table 5-3 for the discharge time, current rate, and variable resistor value for the battery to

be tested.

(c)

Connect the switch (item 7, app E), variable resistor (item 8) and test equipment as shown in figure

5-1. Two multimeters (AN/USM-223) are required. Charger/Analyzers as indicated in 5-3i, may be used in

place of resistors. Check Charger/Analyzer literature to determine if the particular battery to be tested can be

operated on the specific Charger/Analyzer.

(d) Begin the discharge capacity test

(e) When the battery has been discharged for the specific time, at the rate indicated in table 5-3,

measure the closed circuit battery terminal voltage and then as quickly as possible, the individual cell voltage.

(f)

The battery terminal voltage should be as specified in table 5-3. If any cell is less than 1 volt, stop

discharging and mark the cell(s) which measure less than 1 volt for replacement.

(g) If batteries are discharged at a higher rate then specified in table 5-3, refer to section 2 for

applicable capacity at the specific rate.

(h) If all cells are 1 volt or greater, stop discharging and recharge the battery (f above). Allow the

battery to rest and adjust the electrolyte level (para 5-6). Proceed to 2 below.

Table 5-3. 2 hour Discharge Capacity Test

Figure 5-1. Capacity test Connection Diagram

5-6. Adjusting Electrolyte Level.

CAUTION

For batteries requiring electrolyte adjustment, be sure to perform the charging

procedures given in paragraph -5-f These procedures must be followed to prevent

overfilling cells that have marginal headspace. Overfilling will cause spillage of

5-3